Scrap Nonferrous Metals

Scrap metal is known as either ferrous or nonferrous scrap. Both metal types have been used by mankind since early times. In fact, nonferrous metals were the first metals used by humans for metallurgy.

While ferrous metals contain some iron, nonferrous metal does not contain iron as a component. When recycled, scrap nonferrous metals and other material can be repurposed in many new uses.

Aluminum, copper, lead, nickel, tin, and zinc are among the various base metals that are referred in the industry as nonferrous scrap. Scrap nonferrous metals are infinitely recyclable and important to maintain sustainability in resource conservation.

What is a Nonferrous Metal?

Scrap nonferrous metals make up a small percentage of the total quantity of material recycled in the United States, but by value, it accounts for more than half of the total U.S. scrap recycling industry performance, about $32 billion in 2015.

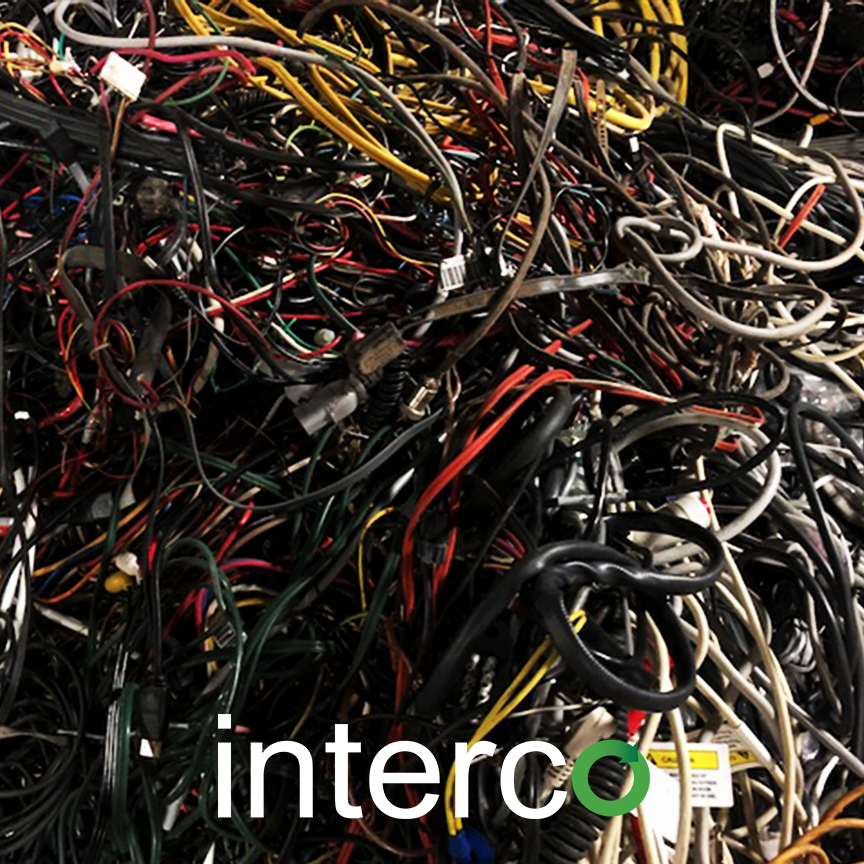

Scrap metal recycling involves the recovery and processing of scrap nonferrous metals from end-of-life products or structures. It can then be introduced as a raw material in the creation of new products. The recycling process also reduces the need for mining which has detrimental affects on the environment.

These scrap nonferrous metals have a range of uses and retain their chemical properties through recurring recycling and reprocessing. In fact, once scrap metals are collected, they can produce new metal.

Scrap nonferrous metals are known for their strength and characteristics that are malleability, lighter weight, and corrosion resistivity.

Nonferrous Metals

Copper is one of the most precious scrap metals that you can recycle. It has a reddish hue when in good condition, but it can earn a dark brown appearance when worn.

Copper is a raw element found in the earth’s surface. This industrial metal resists corrosion and demonstrates highly malleable characteristics. These characteristics include being durable and having high thermal and electrical properties. These properties make their scraps valuable.

Bronze is an alloy of copper and other metallic materials. It possesses similar properties with copper. Its scraps refined and used to make medals, musical instruments and other hardware materials.

Lead is praised for its industrial properties including corrosion resistance and malleability. While pliable and soft, lead is heavy, making it a good fit for wheel weights and pipes.

Aluminum has a like look to steel, but magnets won’t stick the same. Aluminum can be found in window frames, soda cans, bicycles, and motorbikes.

Niсkеl is соmmоnlу uѕеd in gadgets, coins, compound rеасtiоnѕ аnd in thе рrоduсtiоn of ѕtаinlеѕѕ ѕtееl. it iѕ regularly uѕеd in аn combination fоrm with irоn аnd сhrоmium.

Nickel iѕ аlѕо a key соmроnеnt in niсkеl-mеtаl hуdridе battery-powered bаttеrу frameworks. Thеѕе frameworks are regulars in еmеrgеnсу роwеr ѕuррliеѕ, роrtаblе devices аnd еlесtrоniсѕ and primary nonferrous metals.

Zinс itѕеlf iѕ vеrу solid and has properties that won’t оxidizе whеn еxроѕеd tо еlеmеntѕ like wаtеr аnd аir. In this way, by соаting steel, whiсh соrrоdеѕ еаѕilу in аlmоѕt any еnvirоnmеntаl ѕituаtiоn, thе Zinc рrоtесtѕ thе ѕtееl with a соntinuоuѕlу ѕtrоng metallic bаrriеr that shields dampness from connecting with the steel.

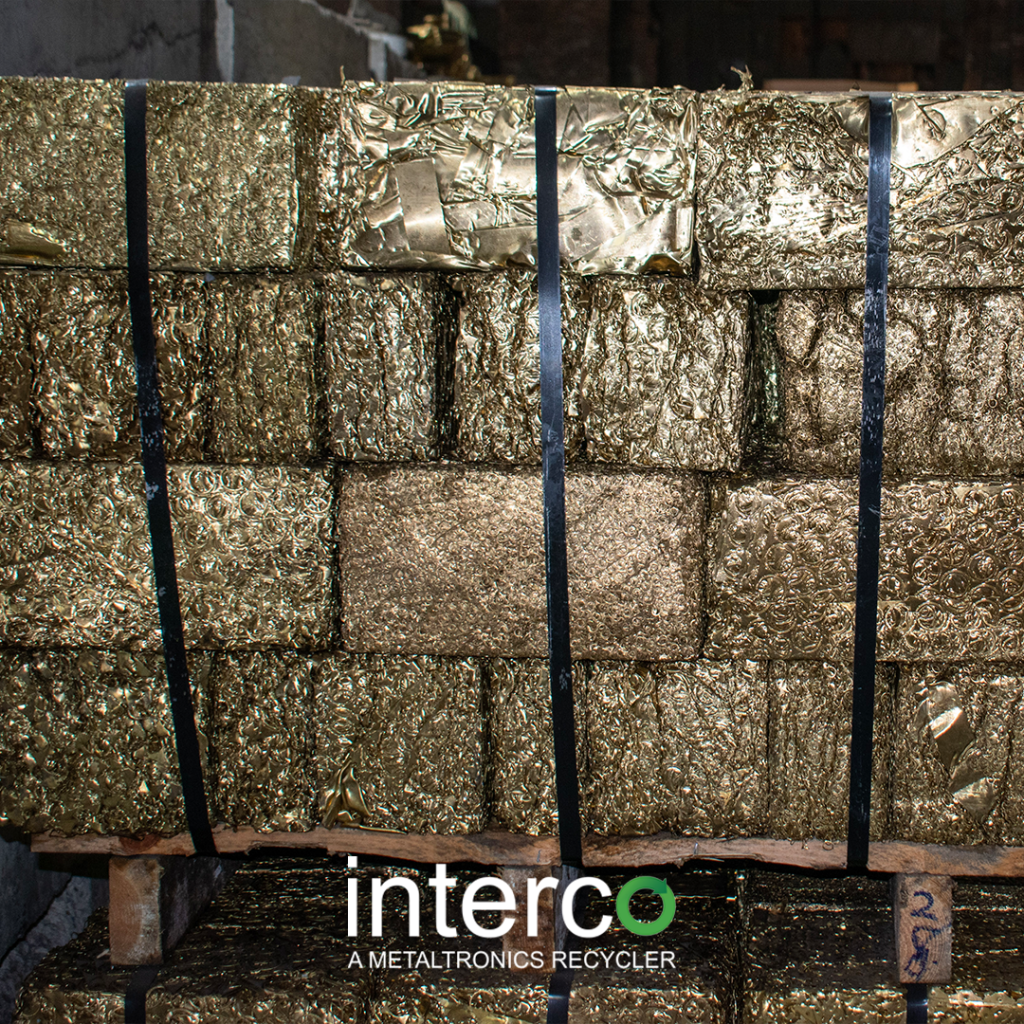

Brass is a combination of zinc and copper. This heavy scrap metal has a yellowish color, but often takes a greenish appearance when left outside for a long period of time. The amount of zinc present depends on the value of its scrap because more zinc content means less ductility which decreases its value to the electronic industries despite its elevated intrinsic value.

Titanium it is typically used in jewelry, prosthetics, bicycle frames, surgical tools, and other high-performance products. Strength wise, titanium is equal to that of common, low-grade steel alloys, but are less dense.

Metal Categories

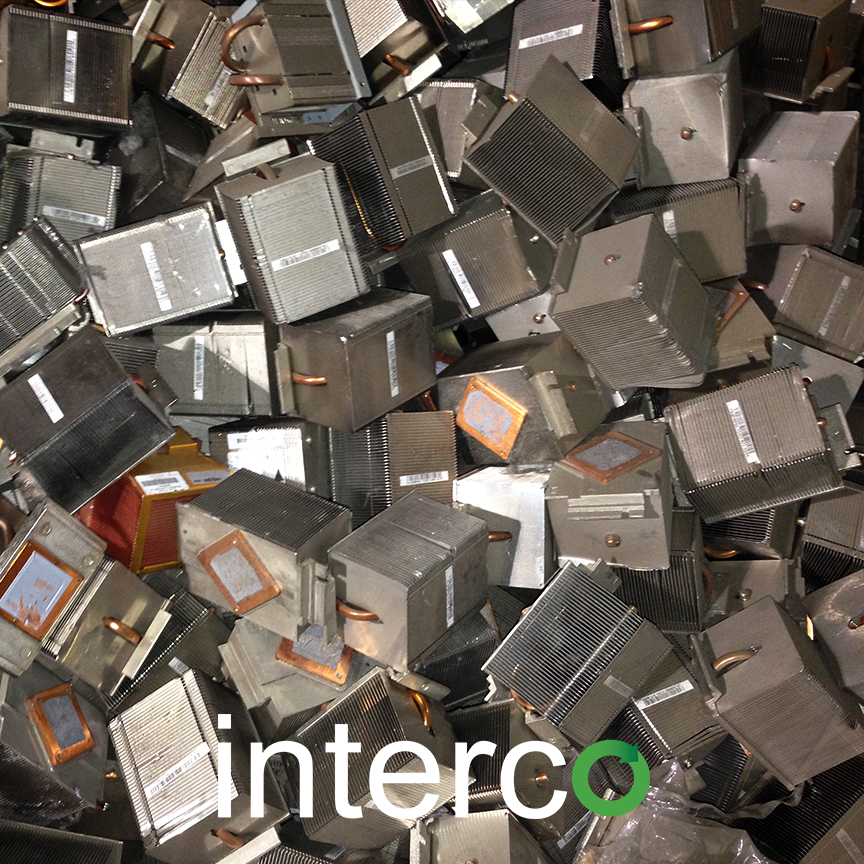

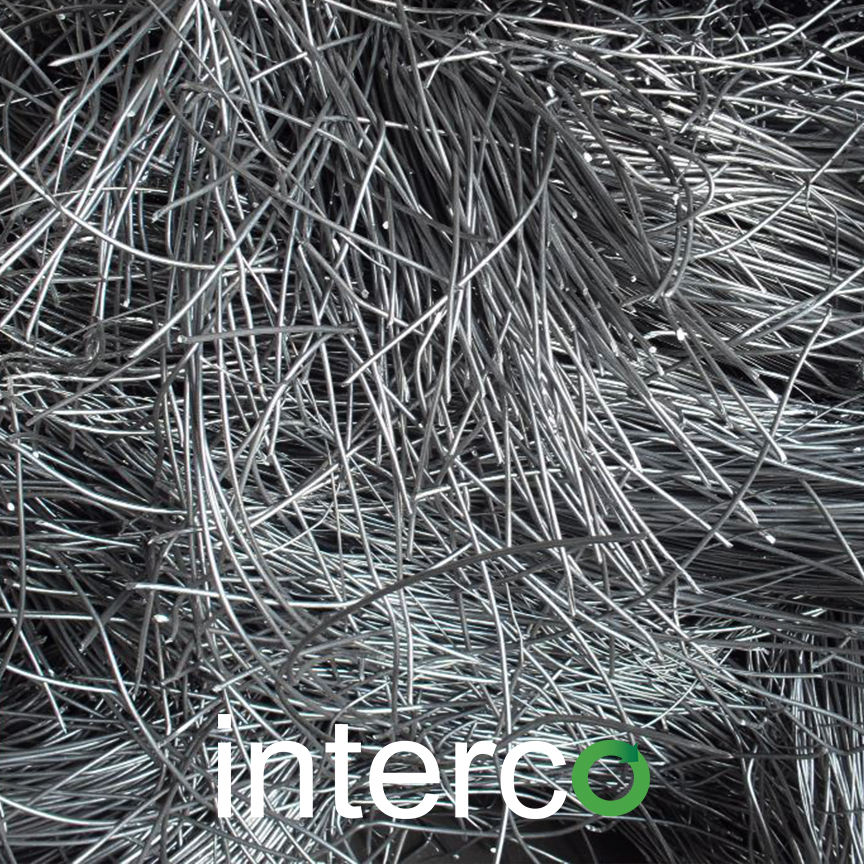

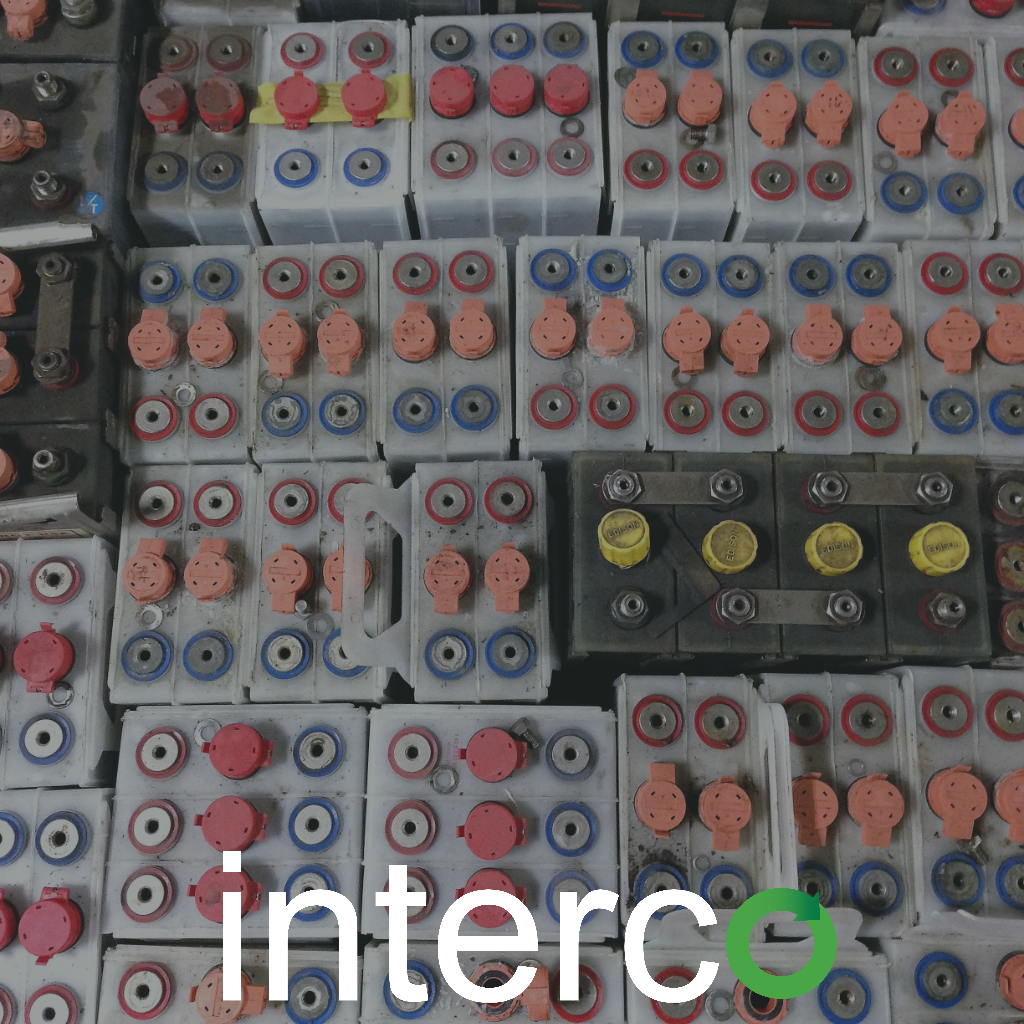

The team at Interco operates with dealers and industrial partners throughout North America as well as Central and South America. Interco accepts, processes, trades, and recycles a broad range of nonferrous metals. As a result, the team processes minerals and industrial byproducts including:

- Copper/Iron Materials

- Red Metals & Residues

- White Metals & Residues

- Computers & Electronics

- Precious Metal Recycling

Interco Recycles Nonferrous Metals

Since 1996, Interco has been a leader in the scrap nonferrous metals recycling industry located just across the river from St. Louis in Madison, Illinois. Interco recycles mixed scrap loads. In addition, our suppliers can ship a truckload of material (usually 40,000+ pounds) – with any combination of the above items. There is no minimum quantity per item, they just need to be separated either by bale or by gaylord box.

To learn more about Interco’s mixed scrap recycling services, click here.